![]()

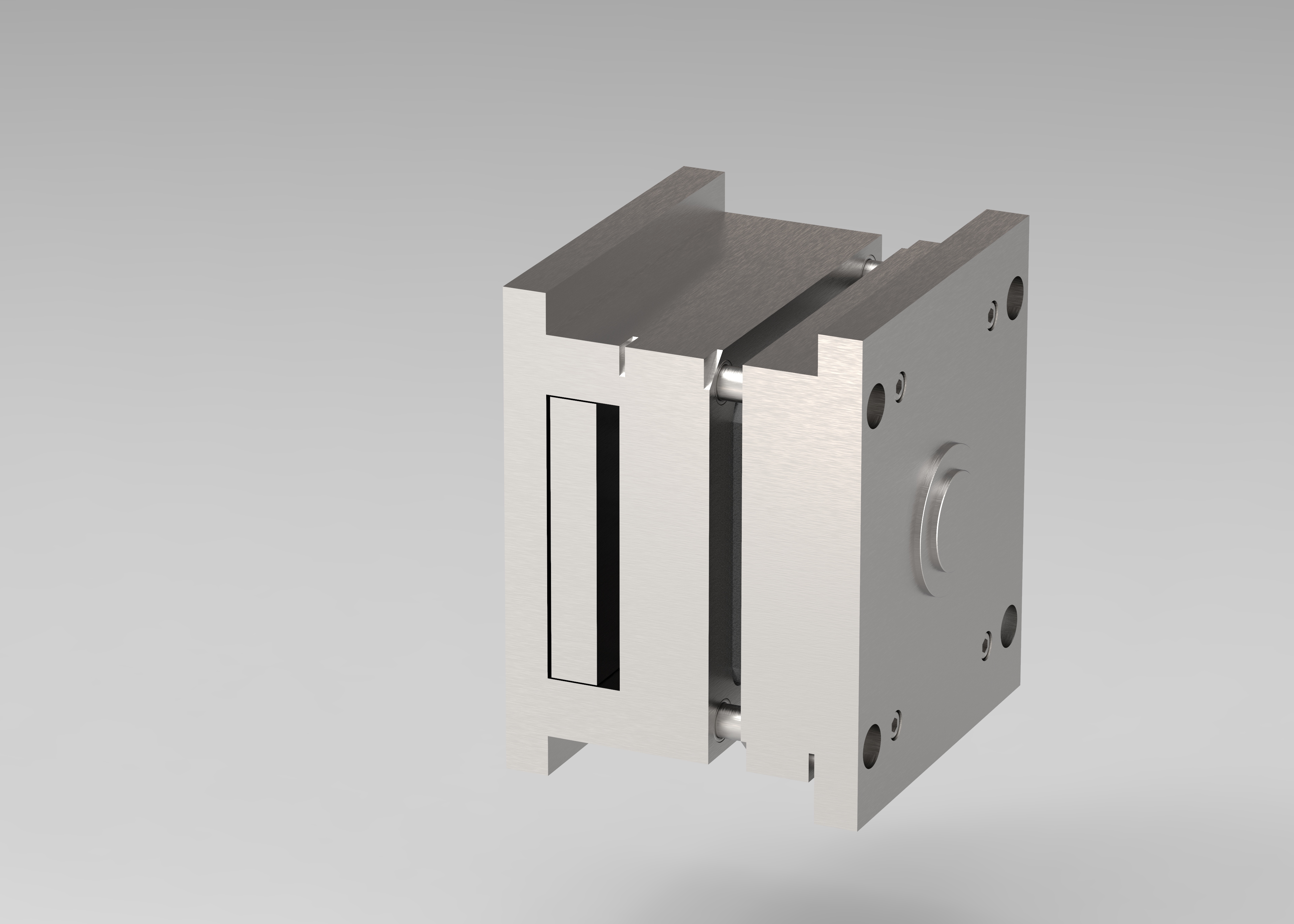

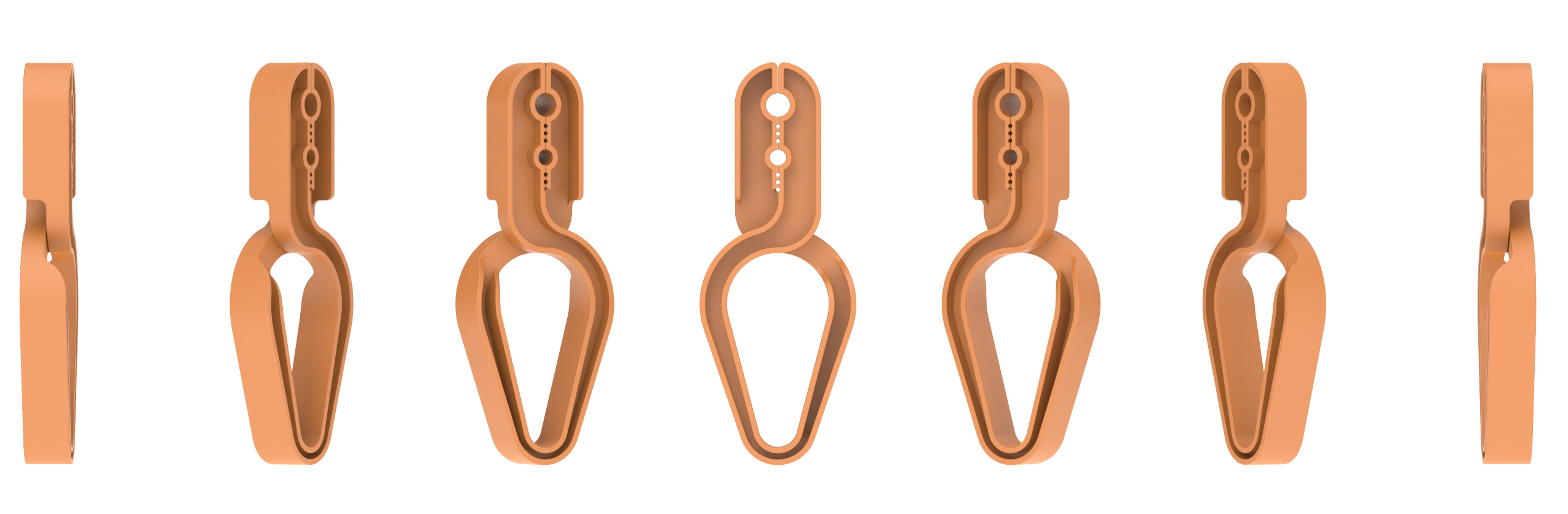

Monopin consists of the development of a single-piece plastic clothespin and the consequent design of its correspondent injection mold. The proposed design offers a contraction and compression mechanism for opening and closing through the tensions generated by the force applied by the user. This pressure originated in the grip zone will close the radius of the lower part, which will try to return to its natural position, thus acting as a spring.

The walls have been extruded at one mm thickness around the perimeter of the part to lighten it, give it rigidity and provide a good contact area for the user and the objects being held. Following the same standards, we have applied the same thickness throughout the piece except in the area that produces the spring effect for volumetric reasons and to offer greater resistance to bending.

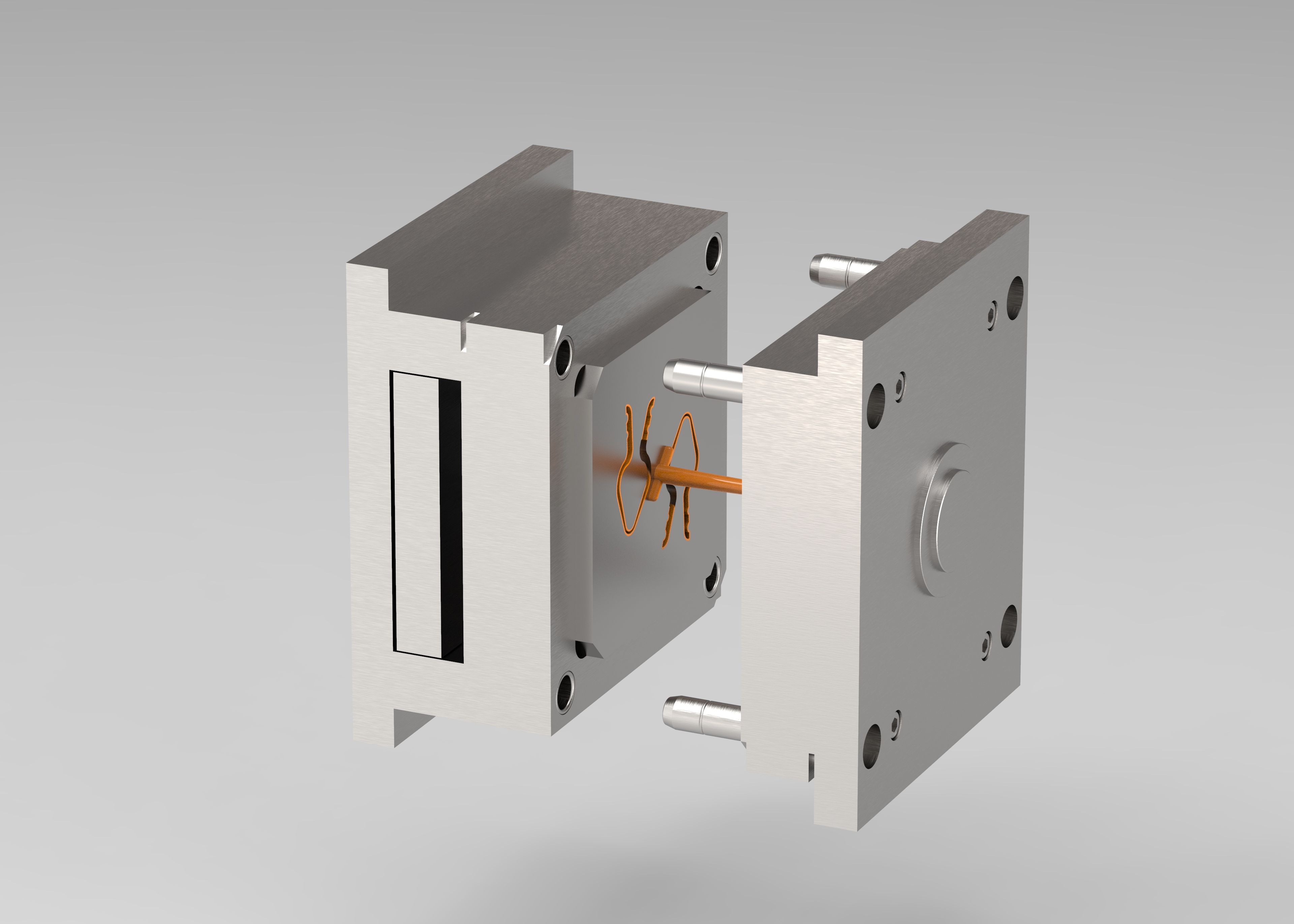

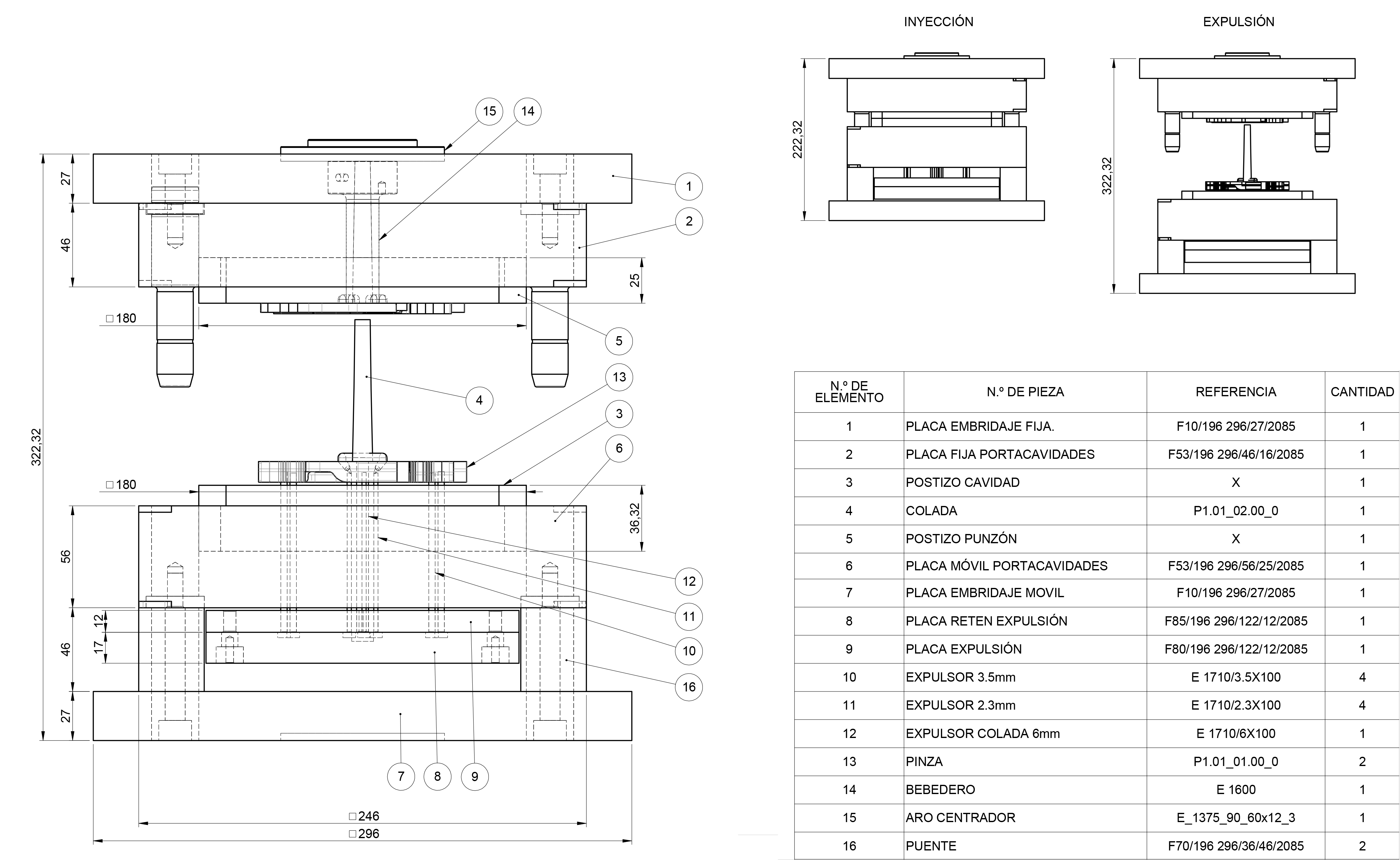

The mold for the injection process has been developed with the assistance of Meusburger mold provider, using a submarine entrance for best flow through the geometry. After doing the calculations for cycle duration, necessary force of the injection machine and material cost, the final production cost is of 13 cents per piece.